In 3D printing, wall thickness refers to the distance between one surface of your part and its opposite sheer surface.

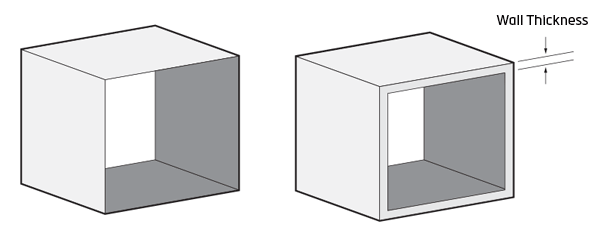

When using your 3D modeling software it is possible to design a surface without a wall thickness, see left picture below. It is important to make sure that that every surface of your 3D file has been assigned a wall thickness because 3D printers need the information about how thick you intend the wall of your object to be.

Before you decide to 3D print (or even design your model), you should know the basic guidelines for your printing material of choice. You can find specific information about the required wall thickness for each material in our material design guides. For every material there is a minimum wall thickness that we recommend your model to have at any time in order to prevent problems. Many printing problems can be traced back to wall thickness issues. The minimum recommended wall thickness depends on the material you choose. Other factors such as the alignment, size, and overall design of your 3D file, can also influence the minimum wall thickness that we recommend.

Our recommended minimum wall thickness are designed to assure a reliable printing result. Printing lower wall thicknesses can however be possible and interesting, for instance for the use of hinges, see the article: What are living hinges?

Minimum wall thickness

Minimum wall thickness indicates the lower limit of how thin a wall can be printed in. However, we always recommend to be on the safe side and make the walls a bit thicker.

Maximum wall thickness

Besides walls that are too thin, you might also encounter problems with walls that are too thick as well: for materials such as metals, it is especially important to respect maximum wall thicknesses, as thicker sections will generate too much internal stress and could cause the item to crack or even break.

Too thick walls can be a reason why we can't print some of your orders. The best solution is to make your model hollow and foresee holes to let the powder flow out: Once again you need to check the individual guidelines on how big these holes need to be: 3 mm for small models (less than 10 x 10 x 10 mm)..

Let’s take a look at an example where maximum wall thickness plays an important role: If you want to print a somewhat flexible object in polyamide (like an iPhone case that needs to be clipped onto a phone), walls that are too thick might turn a flexible object into an item that is too bulky. In this case, a thickness of 1.5 to 2.5 mm would be ideal for creating a somewhat flexible product.