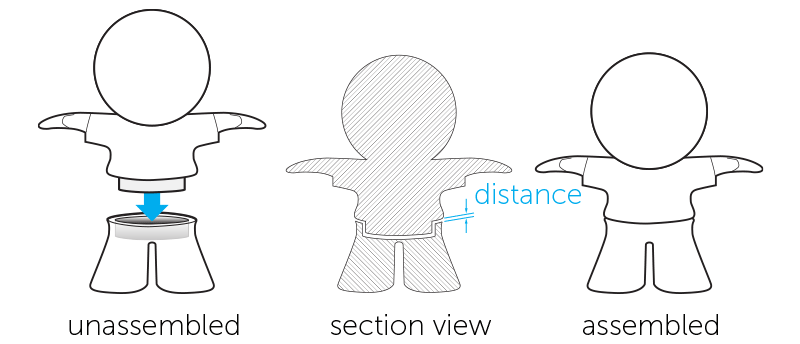

Assembly clearances

Parts that are to be assembled after printing, need to have sufficient distance (clearance) to adjoining surfaces.

This is necessary

- to enable the removal of powder, resin or support depending on the chosen technology

- to account for minor deviations caused by the 3D printing tolerances and

- to help with the friction between surfaces during the assembly

The following table shows an overview of recommended clearances for the most suitable materials:

| Technology | Materials | Recommended clearance for parts of an assembly |

| Laser Sintering | Alumide, Polyamide, Polypropylene | 0.6 mm |

| Fused Deposition Modeling | ABS | 0.3 mm |

| Stereolithography | Gray Resin, Mammoth Resin, Standard Resin, Transparent Resin | 0.6 mm |

| PolyJet Printing | High-Detail Resin Multicolor+ | 0.6 mm |

For more information on threads for screw connections of parts, please consult the article: Adding screw threads to your 3D printed model.

Additional clearances for painting and gluing

- When surfaces are painted, please foresee an additional +/- 0,2 mm of clearance on each painted surface to account for the paint layer.

- When parts of an assembly are glued, foresee an additional +/- 0,2 mm of clearance between the surfaces to account for the glue connection.